The flames of the gas furnace echo through the dimly lit workshop.

The sound of metal hitting metal with a pleasant rhythm stimulates the ears.

───The heart and soul of Japanese manufacturing resides in this place.

The atmosphere is so strong that you can feel it intuitively.

Hinoura Knife Workshop, a blacksmith shop with a history of over 100 years in Niigata Prefecture, retains a sense of pride that must never be lost, no matter how much time passes.

Sanjo, the town of blacksmiths. The most attractive attraction in Japan

“I’ve seen many different cutlery production areas with my own eyes, but I haven’t found a production area like Tsubame-Sanjo in all of Japan,” says Tsukasa Hino, a third-generation blacksmith, as he slowly lights a cigarette. (hereinafter referred to as Mr. Tsukasa) declares this with a confident expression.

The Tsubame-Sanjo area of Niigata Prefecture, where Hinoura Knife Workshop is located, is one of the best hardware towns in Japan, with family-owned and medium-sized factories crowded together.

Sanjo’s metal processing techniques, which began with the production of Japanese nails in the Edo period and developed, have continued to be passed down into the Heisei era, and the reputation of its craftsmanship has spread across the ocean, reaching far overseas.

“All metal processing can be completed in this city. I have visited seven major cutlery production areas in Japan, and there is no other production area like this.”

There was a blacksmith, and there was a person who sold them…

There used to be over 500 wholesalers in this area.

Although the number has decreased, there are said to be 180 of them.

About 10% of this is wholesale of cutlery. The absolute number is overwhelmingly different from other production areas.

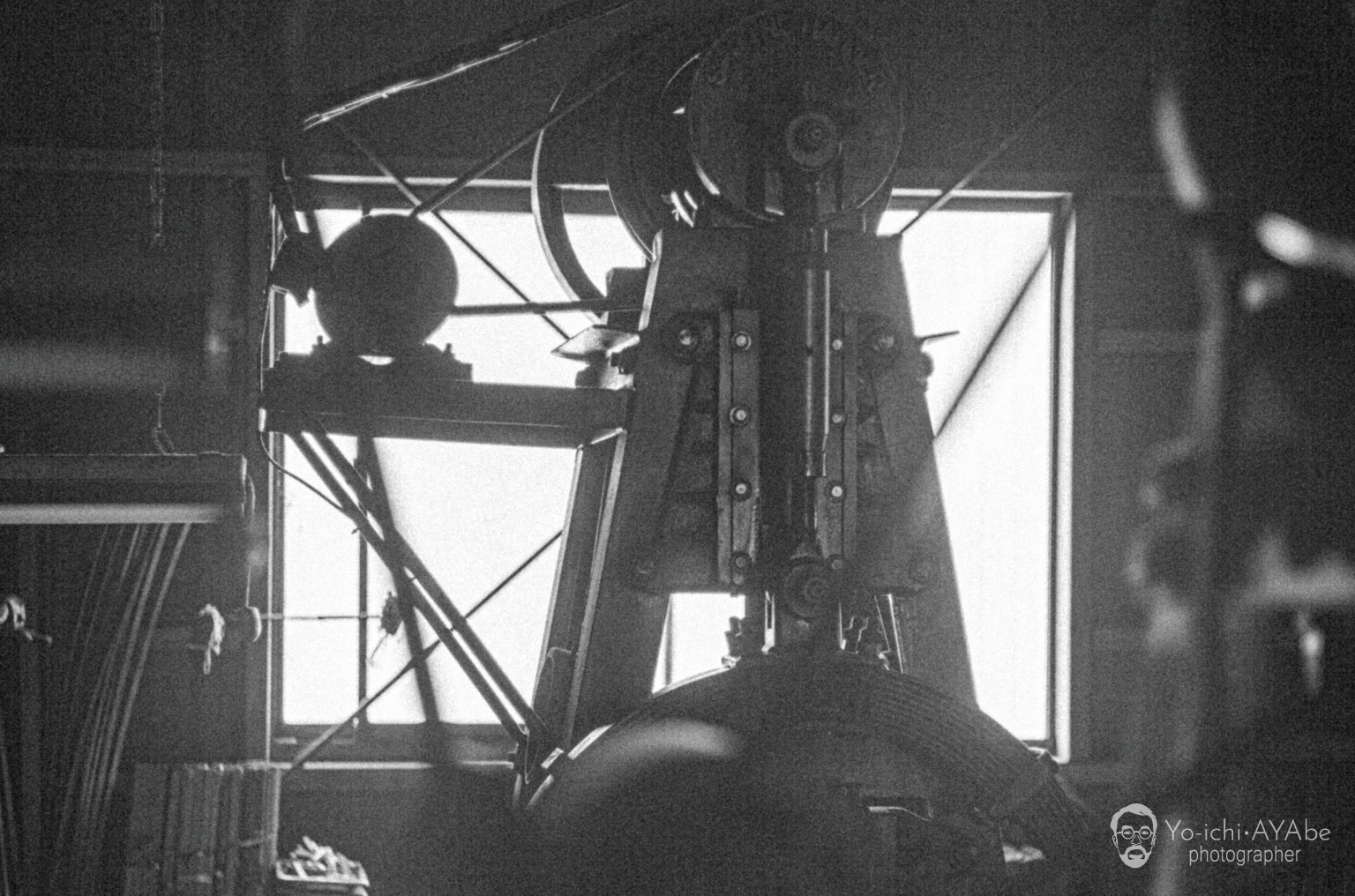

The old spring hammer from around 1955, which Mr. Tsukasa had inherited from a senior colleague, didn’t even have the parts at the time, but because he was in Sanjo, he was able to get it repaired by calling a nearby business on the phone. . This is because the city of Sanjo has the power to create things from scratch.

“I think it’s because of Sanjo that the demand for this area hasn’t dropped much in the market even now.People in Sanjo should also be more aware of their own charm.”

Japanese blacksmithing technology is appreciated overseas

Surprisingly, it may be that overseas consumers understand the appeal of Japanese blacksmith techniques more than domestic consumers. One day, when Mr. Tsukasa went on a tour to Europe, where he sells products, people from other countries were naturally interested in Japanese knives. He was often asked, “What is the maintenance of Japanese knives and why are they so expensive?” “The reason for this is our technical ability, and the sharpness of our knives is also different from others.”

Japanese cutlery is made for making Japanese cuisine. A characteristic of Japanese cuisine is the use of ingredients. I don’t often put sauce on it like in French cuisine.

And if you want to take advantage of the quality of the material, you will naturally need a sharp knife.

“Even onions don’t stain your eyes if you cut them with a good knife.Japanese tomatoes are soft, but if you cut them with a sharp knife, they cut well without crushing them. stands out.”

More than 10 years ago, when we exhibited at the German exhibition “Ambiente,” among hundreds of thousands of knives from all over the world, Hinoura Knives Studio’s knives were selected for the exhibition’s information booklet.

He has also received many offers to collaborate with overseas designers.

“I was really happy to be recognized overseas like this.It is true that our knives are expensive.In order to explain the difference in price to customers, it is important to experience them and see them with your own eyes. I thought.”

Two options were always looming in front of me.

Business or tradition?

Mr. Tsukasa, a blacksmith, continues to work hard even after gaining fame.

Behind his attitude was a conflict between two options that had troubled him for many years.

“When I first entered the world of blacksmithing, my father, who was the second generation, tricked me into joining the family business by telling me, “If you work hard for 10 years, you’ll be able to build a house.” Up until then, I had never inherited the family business. I was working in sales.”

I knocked on the blacksmith’s door, naively thinking that I could make a living by doing the same thing as his father, but this turned out to be nothing.

At that time, blacksmiths were becoming industrialized and turning into factories. The situation at other factories in the surrounding area has changed rapidly, and the number of orders to Hinoura Knives Studio has decreased.

“When I went to see if all the blacksmiths around me were getting fewer orders, I found out that they were industrializing, becoming faster, cheaper, and changing to keep up with the times.”

Mr. Tsukasa took over the workshop in the midst of these times, always standing in between, deciding whether to invest in equipment and industrialize it like his predecessors, or continue to make a living using the traditional techniques cultivated by his father. I have lived.

In the past, it was said that it was better to become a craftsman than to go to school. Even though blacksmiths became industrialized, it was common for blacksmiths to grow up without any knowledge.

────Anyway, you can make a good knife by hitting it.

“They say you should strike while the iron is hot. If you strike it, it will become a better knife.

I think I’ve just been indoctrinated into it and ended up everywhere. My own father had the same idea. ”

However, Tsukasa, the third generation, had doubts about such trends and ways of thinking.

“When a customer asks me something about knives, I thought that there would come a time when simply saying, “It has been said since ancient times that you can make a good knife by pounding it,” would no longer work.”

What is the quenching temperature? What is the tempering temperature? What about changes in metallographic structure?

At that time, there was no such academic approach.

During these times, Mr. Tsukasa returned to the basics of being a blacksmith and began his studies in order to establish a solid technical foundation and academic basis.

In the future,

I’m sure you can do it with small-scale production of traditional crafts.

“It’s good to use traditional techniques.”

It seems like everyone speaks in unison.

“But then, what does it mean that similar blacksmiths around you have no successors?”

“That means I can’t eat, so is this really attractive?”

Mutsumi Hinoura (hereinafter referred to as Mutsumi), the son of the third generation owner of the workshop, Mr. Tsukasa, and the fourth generation who will be running the Hinoura Knives Studio in the future, will continue to follow his father’s methods even in the future. Be determined to persevere.

“I don’t think we live in an era where you can make money by industrializing and producing large quantities, just like my father said.Isn’t it actually the opposite?Whether it’s traditional methods or small-scale production, it’s not a time where you can make money by industrializing and producing large quantities. If I can add value, I think orders will come.Because it takes time and effort, our products are expensive.Also, we can’t mass produce them and it takes time.Still, there are people who will order them. I think the biggest problem is where and how to bring out this appeal (added value).”

Mutsumi continues to take on new challenges in order to breathe new life into Hinoura Knives Studio.

I was surprised to learn that Mutsumi’s blacksmithing skills were learned by seeing him with his own eyes, without ever asking his father.

“Being a parent and child, there are some parts that are easy to handle and some parts that are difficult,’ says Mutsumi.

He felt a little nervous about the relationship between the father and son of a craftsman. When I tried to find out the reason for this, Mr. Tsukasa told me that after work, when discussing things about manufacturing, they often get into fights.

A vision of the future drawn by the fourth generation, “Amiya”

“There is basically no difference in thinking.”

So Mutsumi speaks again.

“I believe that the “Tsukasa Saku” brand, which is particular about traditional techniques and analog techniques, and the “Amaraya Saku” brand, which supports a certain level of mass production in keeping with the times, are indispensable elements for today’s Hinoura Knives Studio. I am.”

Up until now, it was common for blacksmiths to be inherited within the family.

The more people you bring in from the outside, the more you will have to abandon the traditions you have maintained.

“Therefore, we are a small group of talented people, and I hope to continue running the workshop without abandoning tradition.”

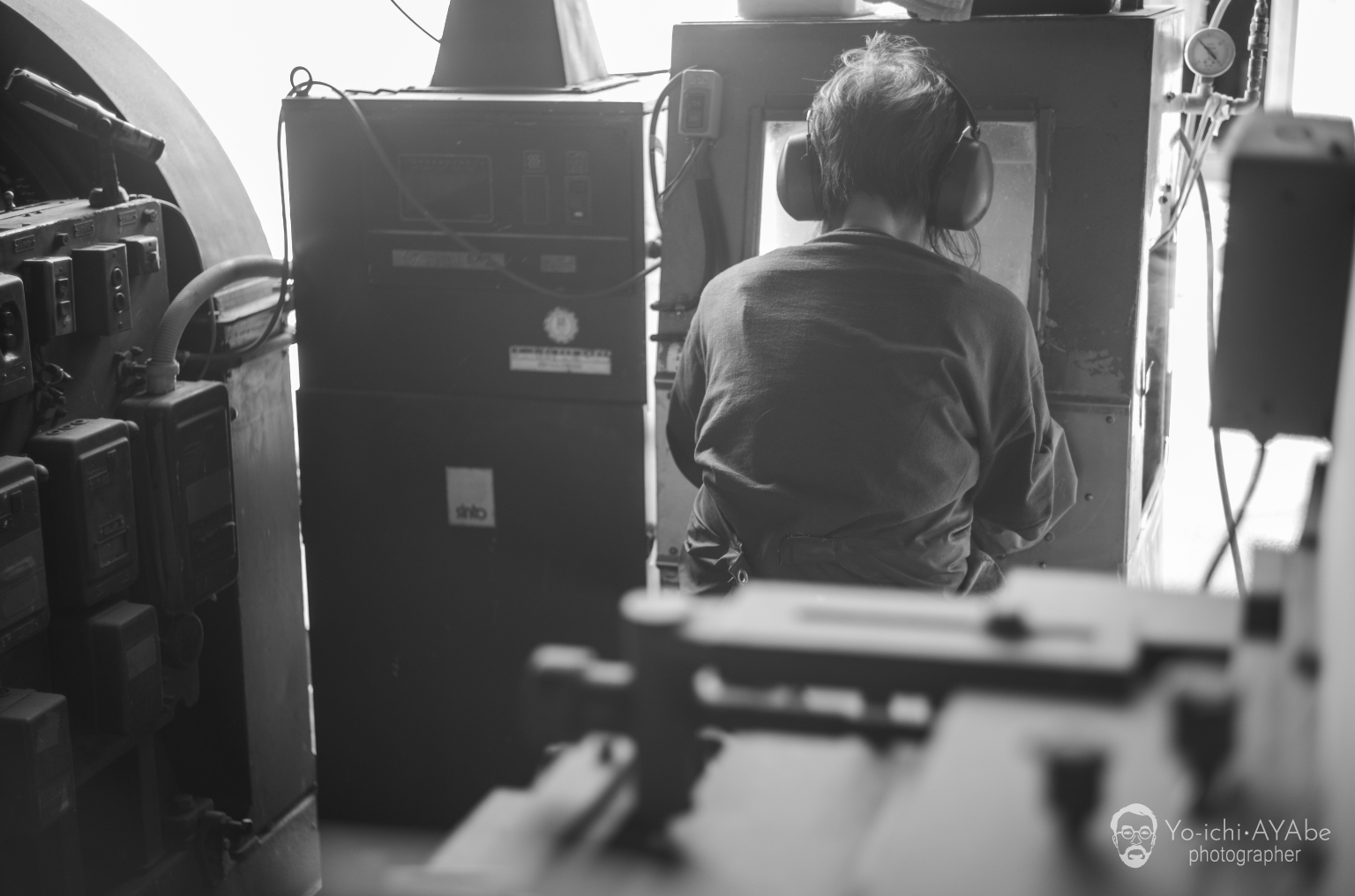

Mutsumi is in charge of the mass production of cutlery in the workshop.

There are many machines here from the previous generation, so women are able to do some of the work.

“There are parts that my mom can tinker with and work on. I think we need to gradually change the way things are done in this way.”

Women may want to do the work that we men take for granted, and women may be better able to make delicate items.

“We need to change the stereotypes of craftsmen themselves,” says Mutsumi.

Adding my way of life as a craftsman to JAZZ

“We don’t listen to enka, we listen to jazz while we compose our songs.”

Mr. Tsukasa loves jazz so much that he traveled to New York himself a long time ago, visited the prestigious jazz club Village Vanguard, and met the owner, Max Gordon.

He says that his days of trial and error as a craftsman have a lot of overlap with the historical background of jazz and with artists.

Still, the way of life as a craftsman at Hinoura Knives Studio is truly rock, regardless of the genre, be it jazz, soul, or folk.

The inseparable bond between parent and child of rock blacksmiths continues to passionately train the souls of these two blacksmiths.

*Refer to the article “Every day is manufacturing”

Photograph